Posted on

In this month’s video, Denton’s Dr. David Douglass, Vice President Marketing and Technology, explains why Denton’s thin film systems are so flexible and easily adapted to suit precise customer needs.

Talk to Denton today to see what we can build for you.

One of the reasons Denton’s thin film systems are so flexible and easily adapted to suit precise customer needs is that all of Denton’s thin film systems, ion sources, transfer hubs, pre-clean modules and process management systems are designed to fit together, almost like Lego™ blocks.

Denton’s Discovery, Infinity IBE, Infinity IBD, Voyager, and Integrity all have similar interfaces for connecting pre-clean components, ion or deposition sources, and handling substrates.

On the Discovery product line, customers can choose to add a single cathode, up to 4 confocal cathodes, a planar cathode, or the patented Isoflux inverted cylindrical magnetron.

The Discovery system block is designed to accommodate any of them.

Likewise, Denton’s Infinity IBE, Infinity IBD, Voyager, and Integrity all have the flexibility to accommodate many different kinds of ion and deposition sources.

For complex, multi-step processes, Denton’s Versa cluster platform can tie all these systems and components into a complete solution – integrated, optimized, and automated for a customer’s precise process.

Substrates can move from one step to another, without breaking vacuum and without requiring human intervention.

The Versa cluster platform comes in a variety of facets, including 4-, 6-, and 8-facets for 200mm wafers and 6-facets for 300mm.

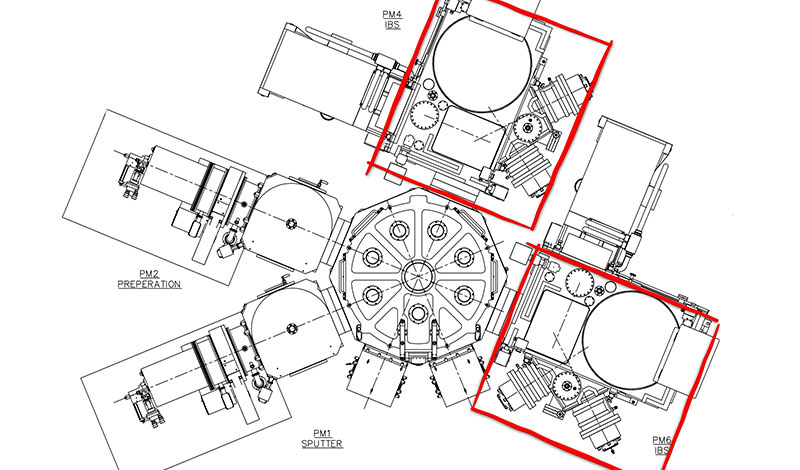

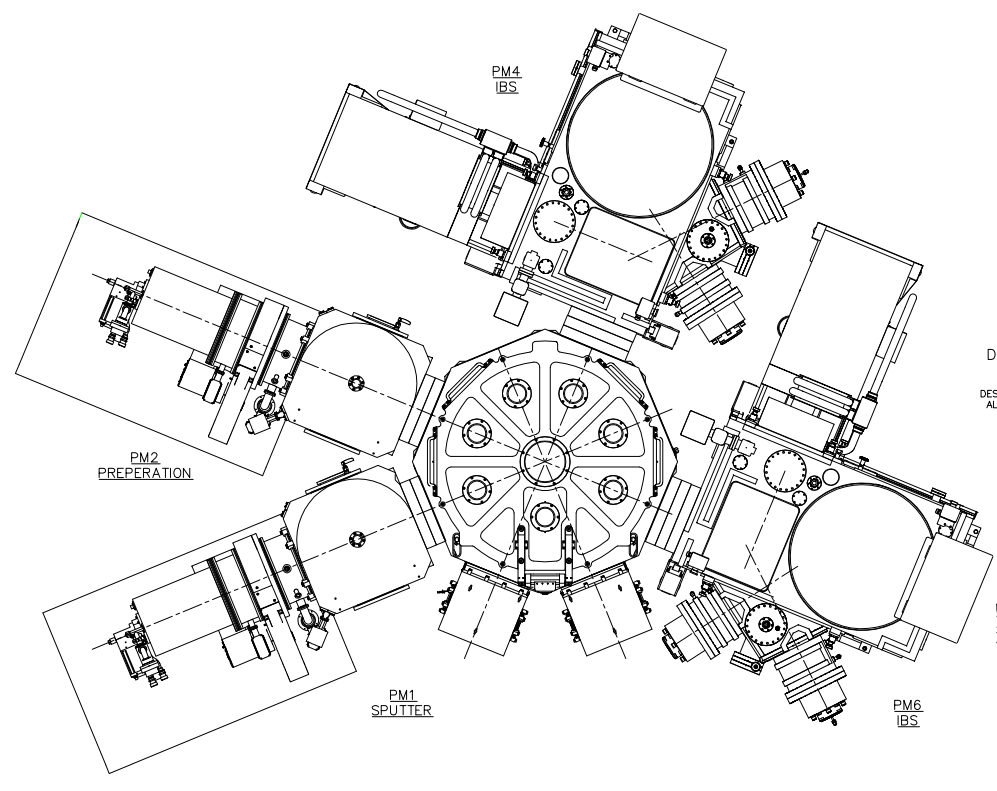

Let’s look at a typical cluster layout to see how this works.

For a configuration designed to produce vanadium oxide microbolometers, we start with an 8-sided Versa transfer hub. From this, we connect dual load locks, enabling the operator to offload a set of finished wafers while another set is being processed. We also add a preparation module, for pre-cleaning and heating of the substrates, and then two Infinity IBD ion deposition systems for vanadium oxide deposition. These can either use the same recipe, as here, to double throughput, or different recipes for a complex, multi-step process. A sputter module rounds out the process with a capping layer on the microbolometer.

This allows a wafer to be pulled from the load lock, passed by the Versa transfer hub to the preparation module, then to the Infinity IBD for vanadium oxide deposition, on to the sputter module for capping, and then back to the load lock for offloading.

Because the vanadium oxide deposition is a slower process, there are two process modules being used here, alternating between them.

The entire process happens automatically, and without breaking vacuum, which is crucial to prevent the vanadium oxide from being exposed to air.

The wafers are loaded into cassettes for easy handling, so the operator never touches the wafers themselves, and the cassettes can easily handle wafers of varying sizes.

The Versa cluster platform serves as the central hub of a nearly infinite variety of configurations.

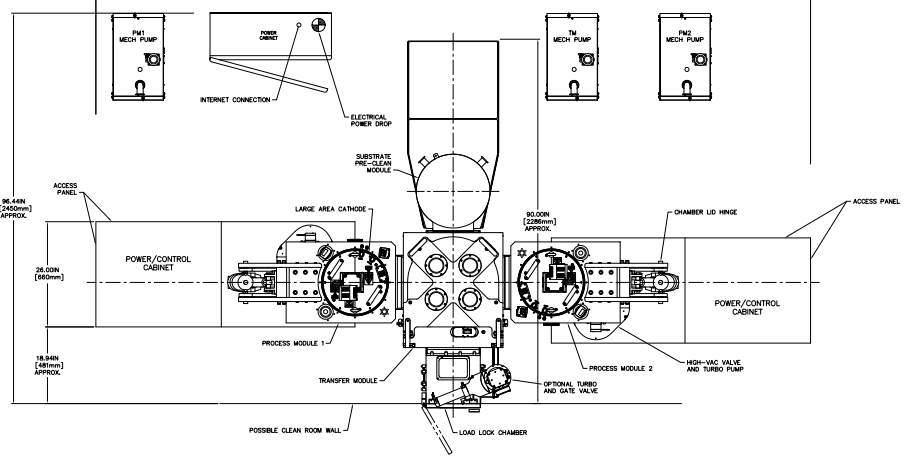

Here, a 4-sided Versa cluster platform is used in an in-line configuration. A load lock begins the process, and the wafers move through the Versa to a pre-clean module.

Titanium is first deposited on one side for a seed layer, with aluminum deposited on the other side for a thick layer. These systems are equipped with large area cathodes, meant to coat large areas in a single pass.

Because Denton’s thin film systems, ion sources, transfer hubs, pre-clean modules and process management systems are all designed to fit together, Denton can build integrated platforms optimized to suit precise customer process requirements.