Benchtop Turbo

The flexible and compact Benchtop Turbo for thermal evaporation and sample preparation is a powerful, versatile high vacuum evaporation and sputtering system.

View DetailsDenton offers a variety of thin film coating solutions for Research, R&D and Quality Assurance (QA) applications, whether that be for sample preparation in electron microscopy, microanalysis in QA, or prototyping in product research and development.

| System | Application | Technology | Substrate Size (maximum) |

|---|---|---|---|

| Desk V | Microscopy | Sputtering Evaporation | 4” (100mm) |

| Benchtop Turbo | Microanalysis | Evaporation Sputtering | 8” (200mm) |

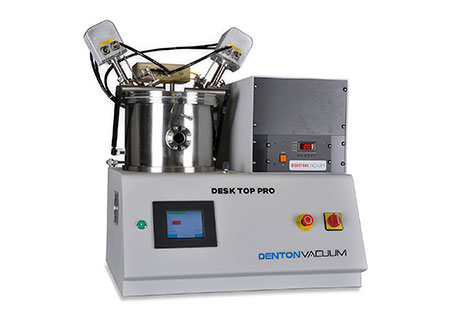

| Desktop Pro | R&D | Sputtering | 8” (200mm) |

| DV-502 | Microanalysis/R&D | Sputtering Evaporation | 8” (200mm) |

| Explorer | R&D | Sputtering Evaporation | 8” (200mm) |

Microscopy is critical to understanding the structure and composition of the materials that make up our world. Biological materials like blood, tissue, and microscopic organisms such as viruses and bacteria are only fully understood when they can be viewed.

In manufacturing, microstructure or chemical analysis is often necessary to ensure product consistency and quality. In addition, manufacturing defects in a high-volume production environment can cost companies millions of dollars if not realized in QA inspection. Electron microscopy and microanalysis offers the ability to see beyond and understand the building blocks that drive the behavior of materials.

Thin film deposition is often necessary to enable or improve the imaging of samples used in electron microscopy. The specific coating materials and techniques vary based on the unique requirements of the sample and the type of analysis. For scanning electron microscopes (SEM), a sample coating creates a very thin, continuous and conductive coating that inhibits charging, reduces thermal damage and improves the secondary electron signal required to generate three-dimensional-like images of the sample surface. For transmission electron microscopes (TEM), fine-grained, transparent, conductive carbon layers coat the sample to support imaged films on grids and backup replicas. Glow discharge for TEM is useful for making the grids hydrophilic.

When preparing samples for SEM or TEM, achieving consistent and repeatable results that are stable from test to test is a challenge. Denton Vacuum’s sample prep solutions are designed to ensure maximum repeatability for the highest confidence in the results, all while saving space in the lab:

Different markets have different driving forces at play, whether it’s the growth of IoT (Internet of Things), consumer demand for smaller and higher-resolution (or touch-sensitive) screens, or concerns for safety and regulations, as in the medical world. At Denton Vacuum, we understand how those unique drivers are shaping the markets we support. Denton solutions are designed to help accelerate and perfect product development and achieve outstanding operational efficiency and return on investment.

Denton Vacuum solutions for R&D are designed for flexibility and versatility, capable of supporting a wide range of deposition methods and thin film coatings in order to enable experimentation and prototyping. Their high accuracy makes it possible to fine-tune product designs through careful iteration.

Denton offers a range of R&D solutions capable of supporting production runs from single, one-off prototypes to small batch pilot projects:

The flexible and compact Benchtop Turbo for thermal evaporation and sample preparation is a powerful, versatile high vacuum evaporation and sputtering system.

View Details

The Desk V Sample Preparation system, equipped for both evaporation and sputtering, is a high productivity solution that delivers exceptional, consistent and highly repeatable results.

View Details

The DV-502 evaporates many of the metals involved in optical coatings, metalizing and electron microscope specimen preparation, including carbon, gold, gold/palladium and platinum.

View Details

The compact and versatile Desktop Pro can support confocal co-sputtering for the deposition of metal and/or dielectric materials.

View Details

The floor-mounted Explorer can handle substrates as large as 8 inches and is capable of support small batch and pilot production. It can be configured for e-beam evaporation, resistance evaporation, or magnetron sputtering. Ion-assisted deposition is available as an option.

View Details