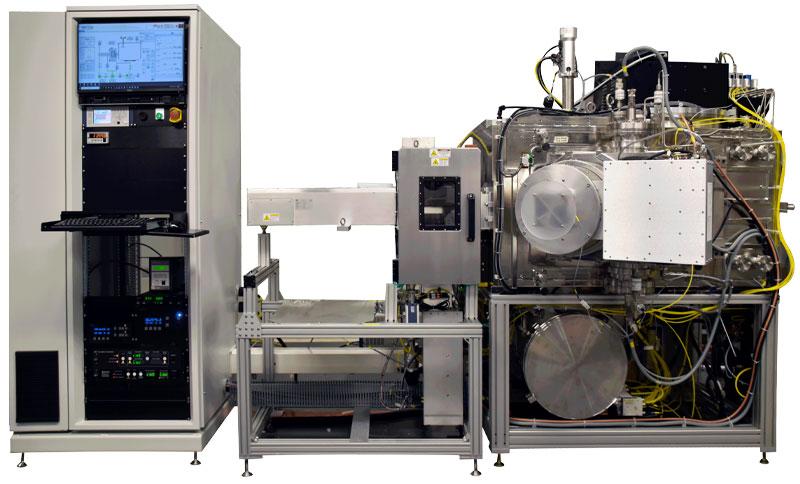

Infinity Ion Beam Deposition Systems

Ion Beam Deposition

The Infinity IBD System delivers dense, lower defects films with extremely high precision and uniformity. It offers independent control over ion energies, so you can achieve exacting thin film specs with very low contamination from flaking.

The Bias Target Sputter module offers excellent control of thin film interfaces, provides independent control over ion currents and energies, and operates at a low pressure. This eliminates contamination and scatter from beam overspill, prevents surface damage, enables tight stress control, and creates dense, defect-free films.

The BTS module improves cost of ownership with increased target usage that allows you to reduce the overall target size. The system design makes it possible to achieve excellent uniformity on large substrates without rotation. The module offers pulsed sputtering and a higher deposition rate compared to other IBD platforms.

All of these unique features and benefits are backed by Denton’s commitment to long-term partnership and service. With our experts, you will receive a highly reliable configuration to meet your needs and specifications that delivers high system uptime and ease of maintenance.

The BTS module enables advanced process control and closed-loop control of film properties for a high throughput.

How it Works

With Denton’s Infinity IBD System, you can achieve higher process performance and thickness uniformity compared to traditional thin film deposition technologies with a production-ready deposition rate. You gain excellent control over adatom energies across a wide range of process pressures, for high repeatability and uniformity.

The system can be configured with an ion assist source for pre-clean and densification, a residual gas analyzer and in-situ controls to monitor specs in real time. Denton’s IBD solution uses an monoenergetic beam of inert gas ions to bombard a target material and create a sputter plume that is deposited onto a rotating substrate fixture.

The Infinity IBD System is ideal for applications like precision optics, AR coatings for lasers, IR optics and other devices where the utmost precision is required. Denton’s IBD module is fully compatible with front-end options, ranging from a single load lock to our Versa cluster tool, to increase throughput and process efficiency.

The Infinity Biased Target Sputter module is designed to enable advanced process control and closed-loop control of film properties for high-performance thin films even at a high throughput. In conventional IBD systems, the long path of high-energy ions between the source and the substrate leads to scatter. However, with the BTS module, high-energy ions only exist near the target, eliminating beam overspill.

Because of its low operating pressure and low ion energy, the Infinity Bias Target sputter module is the ideal solution for next-generation high TCR focal plane arrays, and laser bar facet coatings. This sputter module can be integrated with any front-end option, ranging from a single load lock to our Versa cluster tool, for improved throughput and scalability.

Applications

- Vanadium oxide microbolometers

- Precision optics (lasers, IR detectors)

- VCSEL anti-reflective coatings

- High-efficiency solar cells

- Spin valves for magnetic recording

- Focal plane arrays

- Thermal imaging

- Laser bar facets