Infinity

When you need a high-quality film for demanding applications such as optical interference coatings or x-ray mirror optics, the Infinity Ion Beam Deposition System is the solution for you.

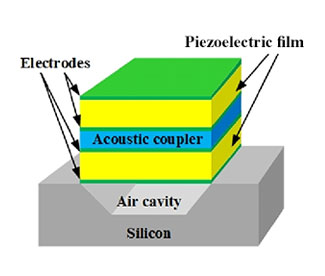

View DetailsSensors are an integral part of the “Internet of Things” and connectivity of electronic systems used in a wide array of industries such as aerospace & defense, automotive, consumer electronics, healthcare, industrial automation and many others. Sensors convert changes in a physical quantity into electrical signals which can be monitored and acted upon by an electronic device. Applications range from monitoring airspeed, temperature, and humidity to reducing interference in cell phone signals.

Thin film deposition technology is emerging as a platform for a variety of sensor applications. Because thin films have a high relative surface area compared to bulk materials, they can be more sensitive to small changes in the local environment. Also, by varying the composition of the materials, the properties of the film can be tailored to suit a wide variety of applications. The simple structure of thin film sensors reduces their cost of manufacture and improves their accuracy and reliability, even under the harshest operating conditions. Also, Denton Vacuum’s thin film ion beam etch technology can be employed to trim individual sensors to meet exacting device performance requirements.

Denton offers the most comprehensive production platforms and application solutions supporting the needs of thin film sensor manufacturing. Denton’s ProcessPro-HV controls platform delivers a number of essential capabilities including high speed factory communication, sophisticated data-logging, remote monitoring and access.

When you need a high-quality film for demanding applications such as optical interference coatings or x-ray mirror optics, the Infinity Ion Beam Deposition System is the solution for you.

View Details

Versa cluster platform is an automated front-end option for high-volume manufacturing. A robotic semiconductor-grade handler moves the substrates from the load locks to the modules to be coated in multiple layers of different materials without breaking vacuum.

View Details