Posted on

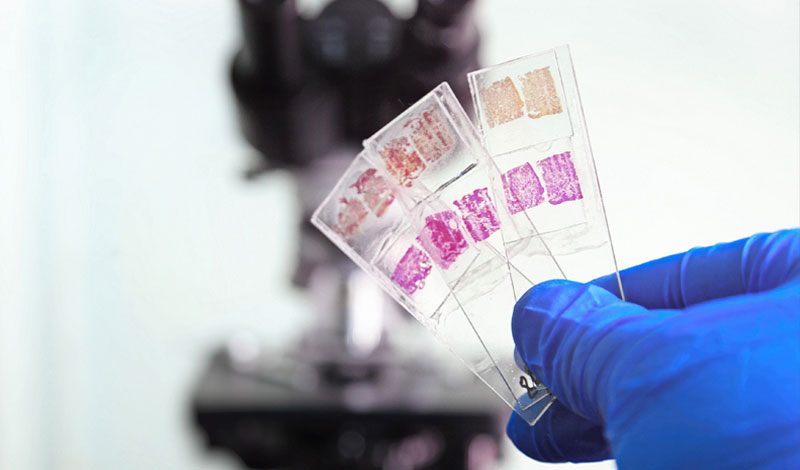

Thin film coating is an important part of the sample preparation process for microscopy. Samples typically undergo a different preparation process depending on the type of microscope being used for observation, but there are two important factors to consider when coating samples for either type.

Scanning Electron Microscopy (SEM) Sample Prep

Biological materials, which include living specimens, must go through a process that includes killing, fixing and dehydrating the specimens. Once the samples are dried, they can be mounted onto a stub for imaging through the microscope. Physical material specimens vary in their conductivity, which affects how they should be prepared for imaging. Metal specimens can simply be mounted on a stub and then imaged, but samples that do not conduct electricity well need to be coated with thin, conductive films before they can be imaged.

Transmission Electron Microscopy (TEM) Sample Prep

During the TEM preparation process, samples are typically sectioned off through ultramicrotomy, which is the process of dividing them into thin 50-70 nm sections and placing on metal mesh grids. They are then stained with electron dense stains so they can be observed under the microscope. A Formvar film is also often applied to the ultrathin sections of the grid for support. These films need to be durable, so they don’t come loose from the grids during the sample prep process.

Important Factors for Coating Samples

Conductivity: For both SEM and TEM samples, conductive coatings are necessary to complete preparation and observe the samples. In SEM samples, a strong secondary electron signal is required to generate 3-D images of the surface. Gold, for example, has a high electron output for secondary electrons, so it’s often used when sputtering coatings for SEM samples. However, for high resolution platinum is preferred. Often a mixture of the two is utilized. Conductive coatings also inhibit charging and reduce thermal damage to the samples from the microscope.

In TEM samples, a conductive coating is also ideal, though the coatings applied are typically carbon layers. These conductive carbon layers support the Formvar film on top of the mesh grid to stabilize the film when it’s exposed to the microscope’s electron beam during observation, ensuring that it remains attached to the gridded sample.

Repeatability: Achieving consistent results from test to test is a challenge in sample preparation, but it’s critical for this sensitive field. Important research of our biological and physical worlds relies on accurate observation of samples in high resolution. The analysis of microstructures and chemicals in manufacturing and production is key to quality assurance of consumer goods and products.

In order to be analyzed and tested properly, samples need to be prepared in a consistent manner. Because coating plays such a big role in preparation and affects the final observation of the sample, the process and equipment used to coat all samples should ensure repeatability.

There are numerous factors that are important to successful SEM and TEM sample prep, including preventing interference. For a more in-depth look at this, read our case study, which discusses how to prevent hydrocarbon background interference during SEM sample prep.