Posted on

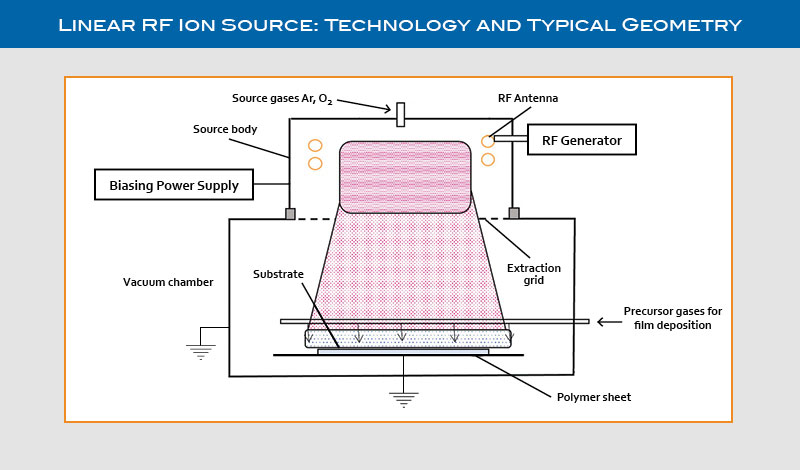

In the world of thin film deposition, there are few techniques that have the versatility of PIB-CVD. Short for plasma ion beam assisted chemical vapor deposition, PIB-CVD is a cutting-edge thin film deposition process that can be used to deposit large area multifunctional thin films with greater efficiency as well as engineer new materials.

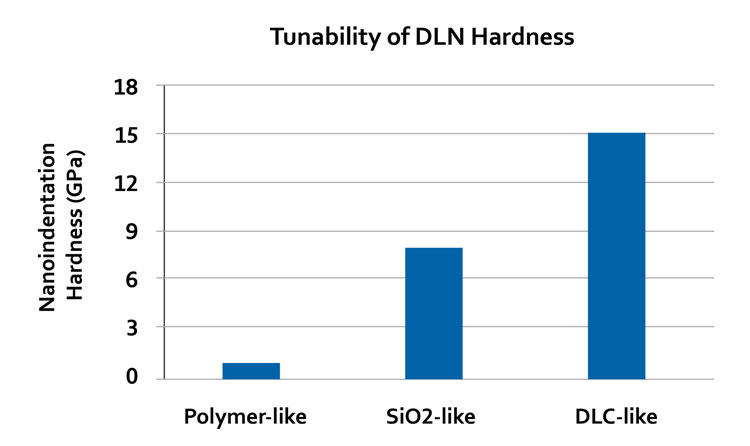

What is unique about this technology is the ability to independently control both the ion energy and ion current density without the need for substrate biasing or high temperatures. This provides the tunability to deposit materials with a wide range of properties even with a single precursor. For example, with Hexamethyldisiloxane (HMDSO), a common PE-CVD precursor used to deposit SiO2, Denton Vacuum has demonstrated the ability to deposit diamond-like nanocomposite (DLN) films with tunable hardness.

In combination with other gas or liquid precursors, it is possible to deposit a wide range of materials even on soft and flexible substrates.

Semiconductor

PIB-CVD can be used for a large number of processes in the semiconductor space, including

- Deposition of dielectric layers such as SiO2, Si3N4, and Silicon Oxynitride films that are crucial for isolation between different components, layers, or metal lines in semiconductor devices.

- Deposition of passivation layers on semiconductor devices to improve their electrical performance and protect them from contamination, oxidation, and moisture.

- Deposition of advanced low-K dielectric films, which reduce power consumption and increase performance in integrated circuits.

- Since PIB-CVD is a low temperature process, it can be used in the fabrication of flexible and wearable electronic devices.

- For multi-level metallization in semiconductor devices, PIB-CVD can be used to deposit interlayer dielectric films that electrically isolate different metal layers and provide a planarizing layer for the subsequent metal deposition.

Optoelectronics and Photonics

PIB-CVD can be used to fabricate optical waveguides by depositing dielectric layers with precise refractive indices. It can be used to deposit anti-reflective coatings on optical components such as lenses and laser facets to minimize light reflection and enhance transmission, crucial for high-efficiency optical systems and lasers.

Surface Engineering and Tribology

PIB-CVD can be used to deposit hard, wear-resistant coatings such as diamond-like carbon (DLC) and silicon carbide on various surfaces to reduce wear and extend the life of mechanical components like bearings, gears, and seals. It can also be used to deposit coatings that have low friction coefficients, minimizing the friction between sliding surfaces and improving the efficiency and reliability of mechanical systems like engines and transmissions. It can be used to deposit coatings that modify the wettability of surfaces, creating hydrophobic or hydrophilic properties as shown below.

This is crucial for applications like self-cleaning surfaces, anti-fogging coatings, and in biomedical devices where controlling fluid interaction is essential. PIB-CVD can be used to deposit films that act as barriers to moisture, chemical attack, or diffusion to protect the underlying substrates from moisture and in chemically aggressive environments.

Biomedical and Biotechnology

PIB-CVD can be used to deposit biocompatible coatings, such as silicon carbide and diamond-like carbon (DLC), on medical implants and devices, reducing the risk of corrosion and rejection by the body. These coatings are essential for enhancing the lifetime and performance of implants like hip joints and heart valves. PIB-CVD can be used to deposit thin films that have antibacterial properties, useful for coating medical devices, surgical instruments, and implants to reduce the risk of bacterial contamination and infection.

Emerging Applications

The future prospects for PIB-CVD are highly promising. Great advances in organo-metallic chemistry have made a wide array of precursors available. This enables PIB-CVD to be used to develop a variety of new materials for emerging applications including flexible and wearable electronics, advanced energy storage, and quantum computing.

Interested in PIB-CVD technology for your application? Learn more about the two Denton Vacuum system options: the Voyager and the Phoenix. Contact us to speak with an applications engineer.