Posted on

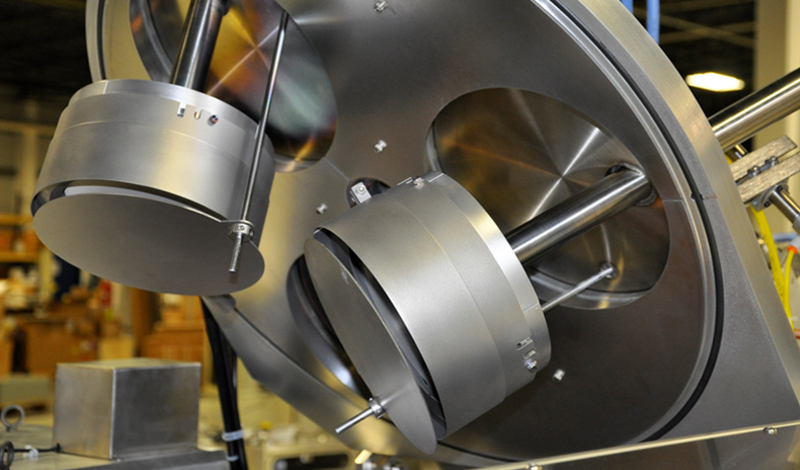

During sputtering, there are several different approaches for cathode placement, depending on what you need to achieve from your process. Positioning the cathodes confocally to the substrate is the preferred method for co-sputtering multiple materials during deposition.

Cathode Placement Approaches

Where the cathode or cathodes are placed in relation to the substrate can have an impact on a variety of factors during deposition, including yield, deposition rate, target material transfer efficiency and uniformity. A cathode may be placed directly above the substrate (planar cathode configuration), or the cathode may have rotating magnets to help with uniformity. A substrate may also be rastered underneath rectangular cathodes during deposition.

Another approach to cathode placement is confocal sputtering, which involves placing multiple cathodes at an angle, instead of directly above the substrate. Like any of the other methods, confocal sputtering has specific benefits and can help optimize your process depending on your thin film deposition needs.

Benefits of Confocal Cathode Placement

By confocally mounting the cathodes around a substrate during deposition, you’ll be able to:

- Deposit multiple layers without breaking vacuum: Confocal placement of cathodes around the substrate allows you to simultaneously deposit more than one material to form a multilayered coating. For relatively low volume applications or R&D, this is often the most cost effective approach to deposit multilayer coatings.

- Handle complex coating processes: You’ll be able to not only deposit multilayer coatings, but with co-deposition also deposit more complex films and compound coatings. This type of process efficiency is difficult to do without breaking vacuum, and becomes a challenge when using a different configuration.

- Minimize your target cost: Because of the orientation of the cathodes when they are placed confocally, the target size only needs to be half the diameter of the substrate.

- Optimize material transfer efficiency: With confocal sputtering, relatively little of the target material ends up on the shields – most ends up on the substrate. For precious metals such as gold or platinum, this can have a tremendous impact on cost of ownership.

Factors to Consider for Cathode Placement Approach

While confocal sputtering offers the above benefits, that does not make it the best approach for every thin film deposition system or coating process. Like with anything else in your configuration, there are important tradeoffs that you need to consider before deciding which approach to take when it comes to cathode placement.

Here are some of the main factors you need to weigh before deciding on an approach:

- Number of materials and layers being sputtered: If your application requires a complex film with multiple layers, it’ll greatly improve your process efficiency if you use the confocal approach to cathode placement. However, if you don’t have the need to deposit more than one material during a single deposition, then you may be able to hit key performance specs with another configuration.

- Uniformity control: Although on its own, confocal sputtering does not yield a very uniform coating, it is possible to gain tighter control of the uniformity by rotating the substrate on its own axis during deposition. As long as your configuration allows for this rotation, you will achieve uniformity within +/- 5% with confocal sputtering. Better uniformity can be achieved confocally, but at the expense of deposition rate and possibly film quality. For tighter uniformity requirements, consider a planar cathode configuration.

- Deposition rate: With the confocal approach, the distance between the source and the substrate (the throw distance) increases as more cathodes are added to the chamber. However, this distance is inversely proportional with deposition rate; the farther the distance, the sharper the decrease in deposition rate. For applications where the deposition rate is a concern, the number of cathodes should be limited to three or four, to ensure the appropriate throw distance as well as thin film quality.

- Throughput requirements: while confocal sputtering provides multilayer capability and reasonable uniformity, it is not the fastest configuration. For high volume applications, consider a cluster tool with planar cathodes, or a multi-cathode in-line architecture.

We take a deeper look at the confocal cathode placement to enable co-sputtering in our technical paper, “Contributing Factors in Cathode Placement for Confocal Sputtering”. Download the paper here.