Posted on

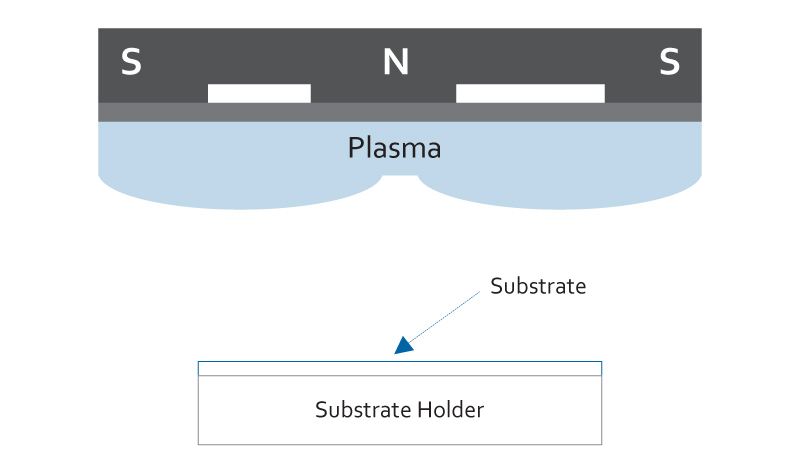

One approach to cathode placement during sputtering is a planar configuration, in which the cathode is mounted directly above the substrate. This is the preferred method for applications where uniformity is paramount to performance.

Benefits of Planar Cathode Placement

When you mount the cathodes directly above the substrate during thin film deposition, you’ll achieve:

- Excellent thickness uniformity control: Because the cathodes are directly above the substrate, and not at an angle, sputtering with this configuration leads to excellent thin film uniformity. The target is also significantly larger than the substrate, which eliminates any edge effect to ensure uniformity. And while uniformity can be improved in other methods (for example, by rotating the substrate), planar placement offers the best uniformity control without any other adjustments to the configuration.

- Uniform thin film quality: Additionally, since every point on the substrate is the same distance from the cathode, the film properties themselves (sheet resistance, index of refraction, etc.) will tend to be highly uniform.

- Improved yield: Achieving uniform thin film properties leads to a higher yield, which is an important factor for cost of ownership.

- Good lift-off capability: For good lift-off, you need a highly collimated, directional sputtering process that is perpendicular to the substrate’s surface. You can achieve this with a planar configuration that has the proper system geometry.

- High throughput: Planar cathode mounting also delivers a high throughput for sputtering, because it allows you to sputter the entire surface of the substrate at once. For high-volume applications, planar cathodes can be used in a cluster tool for maximum throughput and efficiency.

- High deposition rate: Planar mounting of the cathodes helps ensure an appropriate throw distance to the substrate, compared to confocal sputtering, which often requires a farther throw distance to fit in multiple cathodes at an angle. A shorter throw distance leads to higher deposition rates, so a planar cathode configuration helps optimize process efficiency.

Tradeoffs to Consider for Planar Cathode Placement

While the above benefits may be very important for your application-specific needs, there are several important tradeoffs you need to consider with this approach.

- Limited to one material at a time: Unlike confocally mounted cathodes, which can co-sputter multiple materials at the same time, the planar cathode method only allows for one material to be coated at a time. If co-sputtering is not a key process requirement, then this is a tradeoff you can afford to make. However, if you do need to coat with multiple materials or multiple layers, this method may not be very efficient for you, and would end up hurting your throughput if you don’t use more than one chamber. A cluster tool with more than one chamber solves this, but requires a larger capex investment.

- Target cost: Your individual target costs may go up compared to the confocal sputtering method, which only requires the targets to be about half the diameter of the substrate. With planar mounting, you’ll need a target that’s actually larger than the substrate to ensure that the coating covers the entire surface. While the target cost per substrate coated is about the same, if you are coating precious metals such as gold, it may require a significant investment.

- Efficiency of material transfer: To achieve high uniformity with planar cathode mounting, much of the target material will end up on the shields. If you’re depositing precious metals, such as gold or platinum, you’ll likely be sacrificing in terms of your cost of ownership. If your material is relatively inexpensive, then this may be a tradeoff worth making, but it’s something important you’ll need to consider if you’re aiming for efficiency of material transfer. This also needs to be weighed against uniformity requirements for a higher yield, which has an impact on cost of ownership.

Confocal cathode positioning is another approach used for sputtering, and can help address some of these tradeoffs if you have major concerns for your application requirements. Read our blog post on the benefits and factors to consider for confocal cathode placement.