Posted on

The grain size of a deposited thin film is directly affected by the method of deposition. While processing parameters such as deposition rate, film thickness, substrate temperature and vacuum pressure all have strong influences on the grain size of the resulting thin film, they are but secondary factors. The deposition method used has a much greater impact on grain size and, ultimately, thin film performance. Selecting the right deposition method – sputtering or evaporation – is important for the type of film growth desired.

Why Grain Size Matters in Thin Films

Grain size refers to the size of the individual crystallites or particles composing a solid metal. Grain size dramatically affects the physical properties of the entire metal, largely because of the grain boundaries between the individual grains. These interfaces between the grains act as scattering centers, recombination sites, and pinning points.

Larger-grained films, with relatively fewer grain boundaries acting as scattering centers or recombination sites, offer better conductivity but are more subject to wear and malformation.

The relatively higher number of grain boundaries in smaller-grained films increases opportunities for oxidation and decreases the electrical and thermal conductivity of the material while giving the film greater strength and wearability. The Hall-Petch effect makes smaller-grained films stronger and harder, as the grain boundaries impede dislocation movement.

Optimizing grain size in thin film deposition involves finding the right balance between electrical performance (which favors large grains) and fatigue resistance (which often favors small grains).

Why Deposition Method Matters in Determining Grain Size

Two of the most common physical vapor deposition (PVD) techniques in thin film deposition are evaporation and sputtering. Each technique has a different effect on the energy of the deposited thin film. Because the energy of the particles directly affects their migration on the thin film, it’s also a factor in the grain size of the thin film. Particles with higher energy will continue to migrate once in contact with the substrate, whereas particles with lower energy will tend to stay in place. The greater the energy imparted to the particles, the greater the migration and the smaller the grain size.

In evaporation methods (both e-beam and thermal), the coating particles are heated until the material is vaporized within the chamber, so the particles don’t have a very high energy. When the particles condense on the substrate, there is little or no migration present. This makes evaporation an ideal method for applications where a lower-density coating with a larger grain size is best.

In sputtering, particles are ejected from the target with much more energy than evaporation allows. When these particles are deposited onto the substrate, they are much more likely to migrate. If a high-density, smaller-grained film is required, then sputtering is the optimum deposition method.

Experimental Evidence

Denton partnered with the W. M. Keck Laboratory of Structured Light Microscopy and Nanophotonics, Wickramasinghe and Capolino Research Group, at the University of California Irvine to explore the effect that deposition method had on grain size.

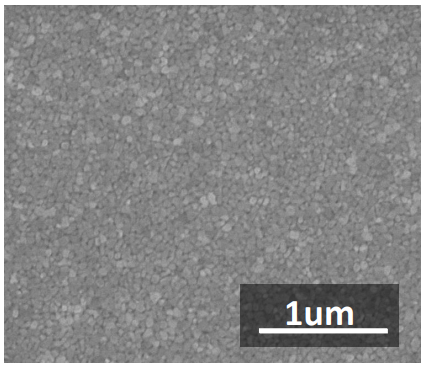

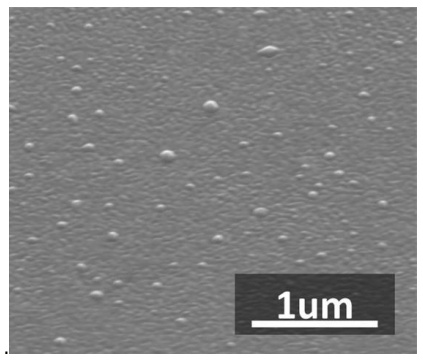

The experiment involved depositing 200nm of gold by both evaporation and sputtering. The resulting films were then compared by scanning electron microscope (SEM) and the grain sizes of the films measured by Atomic Force Microscopy (AFM). The height of the grains on the evaporated film were over two and half times higher than those on the sputtered film and one and a half times wider (that is, in transverse geometry). Visually (see Figures 1 and 2, below), the two films look very different.

Figure 1. SEM image of the Sputtered film

Figure 2. SEM image of the Evaporated film

For more details on the study, download the technical paper, Impact of Deposition Method on Grain Size from the Technical Paper section of Denton’s website.

Choosing the Right Grain Size for Your Thin Film Application

For thin film coatings, the ideal grain size depends on the desired outcome and physical properties, particularly the desired density.

Any thin film PVD process decision must weigh the right balance of system cost, yield, throughput, film quality, and film properties. If you need help making the right selection, contact us – we’re happy to guide you through the process. Denton’s Customer Applications Development Center (CADC) may even be available to set up an experimental comparison of one method versus another.