Posted on

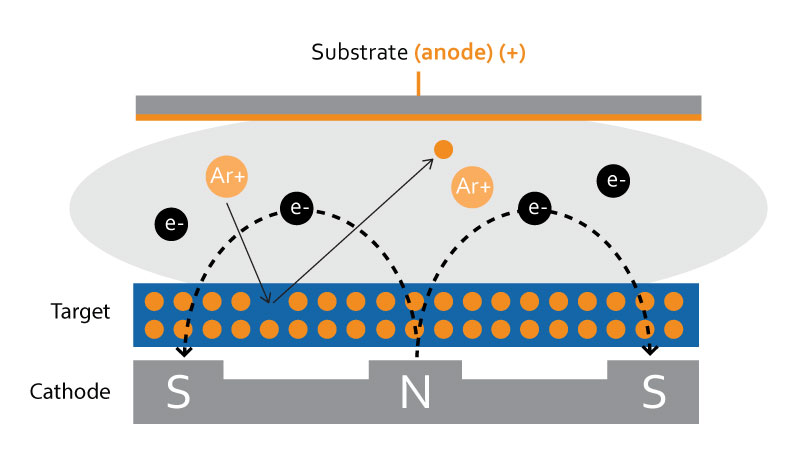

Magnetron sputtering is a versatile deposition technique that creates very dense films with good adhesion. It can easily deposit materials with high melting points that cannot be evaporated. Denton Vacuum’s magnetron sputtering systems are highly configurable with multiple cathode options to meet the specific requirements of different applications.

In this article, we discuss the multiple cathode options for magnetron sputtering – inverted cylindrical, confocal, and large area – and how they help improve production and process performance for applications, including semiconductor device manufacturing, optical coatings, metal coatings, thin film batteries, nanotechnology, OLEDs, and protective coatings.

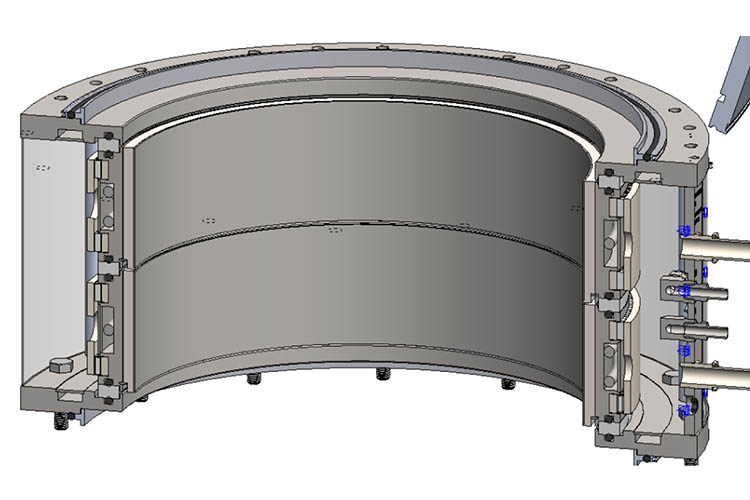

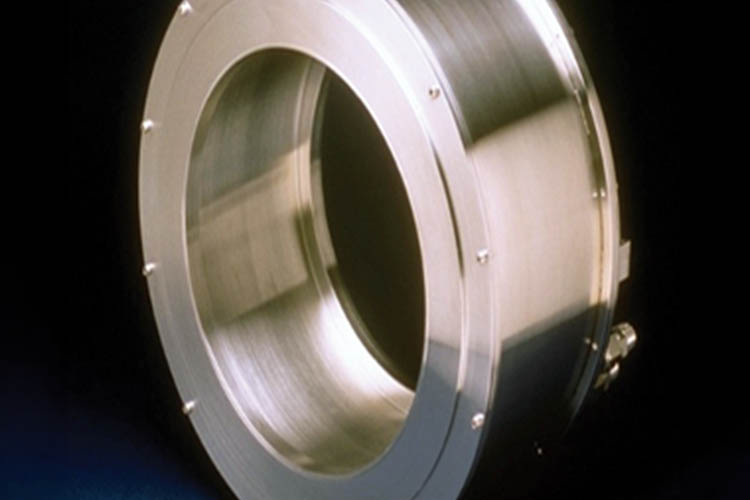

Inverted Cylindrical Sputtering Cathode

Inverted cylindrical cathodes provide superior uniformity on flat and curved substrates and can be configured to coat 3D substrates. For flat substrates such as 8” wafers, the cathode is placed above the substrate. For 3D substrates such as medical stents, the substrate is placed in the center of the cathode and sputtered on all sides, from all directions, to provide uniformity with no masking.

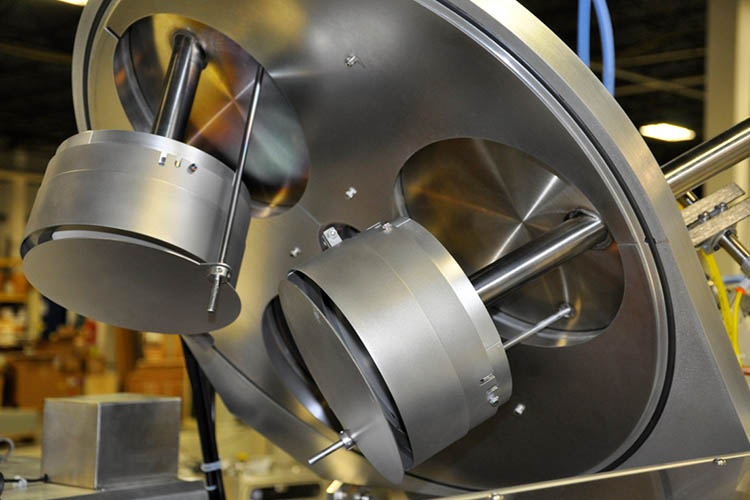

Confocal Sputtering Cathode

Confocal cathodes utilize 3 to 4 cathodes with tri-axis adjustment of radius, distance, and angular presentation to provide good coating uniformity (<±5%) for wafers. This cathode configuration enables the deposition of multiple materials while maintaining vacuum. This minimizes target cost per wafer by optimizing material transfer efficiency, making this cathode option ideal for applications including contacts, optical coatings, laser bars, and ITO (indium tin oxide) electrical coating.

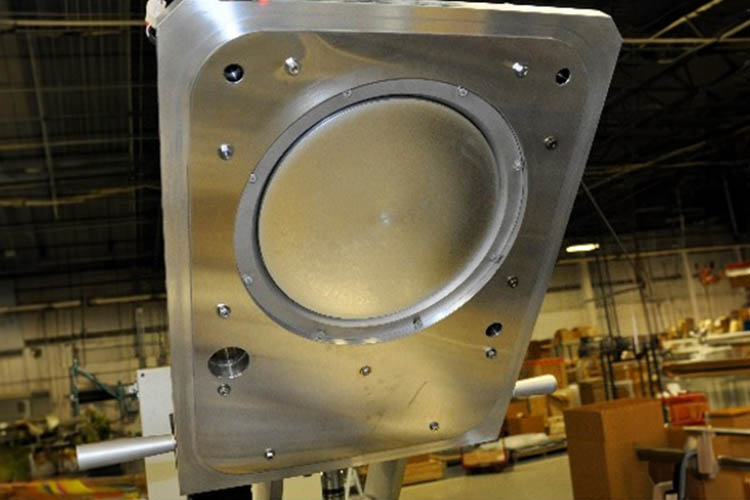

Large Area Sputtering Cathode

Large area cathodes are 12-inches in diameter and offer high-rate, highly uniform deposition. Great uniformity (<±2% depending on material) is optimized by recipe-controlled source-to-substrate adjustment. A large area cathode configuration positions the cathode directly above the substrate for maximum deposition rate and productivity. This configuration is ideal for coating up to 8-inch wafers for power electronics and III-V semiconductors.

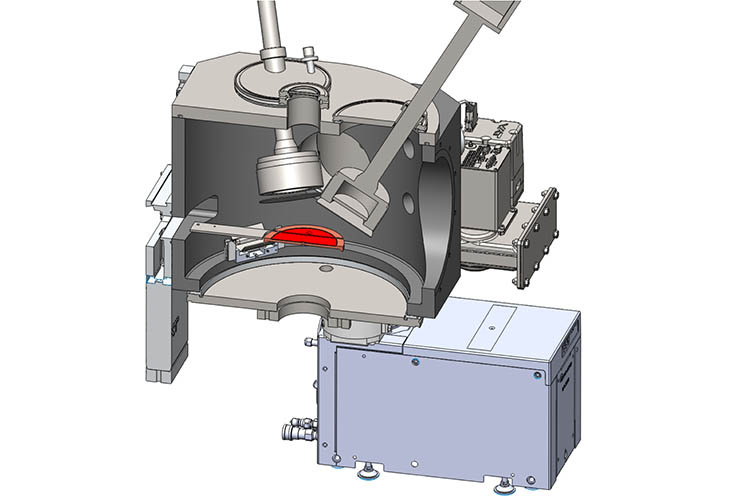

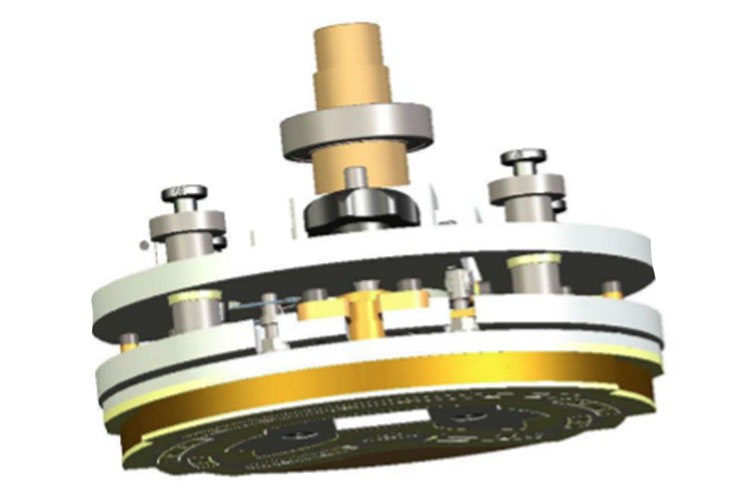

Denton Vacuum’s Proprietary Magnetron Sputtering Solution

The Discovery magnetron sputtering platform is a versatile solution for confocal, planar, and inverted cylindrical sputtering. It conducts both metal and reactive sputtering in a vacuum chamber. It includes an RF bias with dedicated power supply and auto matching network. If you are interested in a magnetron sputtering solution to improve your thin film production process, contact us today.