Posted on

What are Infrared (IR) Bandpass Filters

An optical bandpass filter (BPF) is a device that passes wavelengths within a certain range and blocks wavelengths outside that range. One prominent type is infrared (IR) bandpass filters which are used in a wide range of applications including thermal imaging (night vision), emission monitoring for power plants and factories, aircraft avionics, flame detection for chemical plants, home security cameras, breathalyzers, and environmental monitoring equipment.

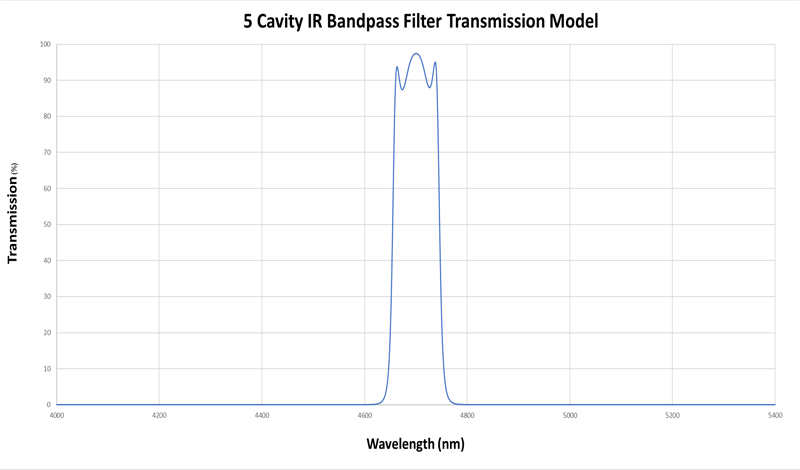

A Multi Cavity IR Bandpass Filter

Bandpass filters are defined by three main parameters:

- Center wavelength

- Peak transmission

- Width of the peak

For many laser applications, achieving the narrowest filter is necessary. This can be achieved by a simple single cavity filter as shown in Figure 1, but it may not be narrow enough for the application.

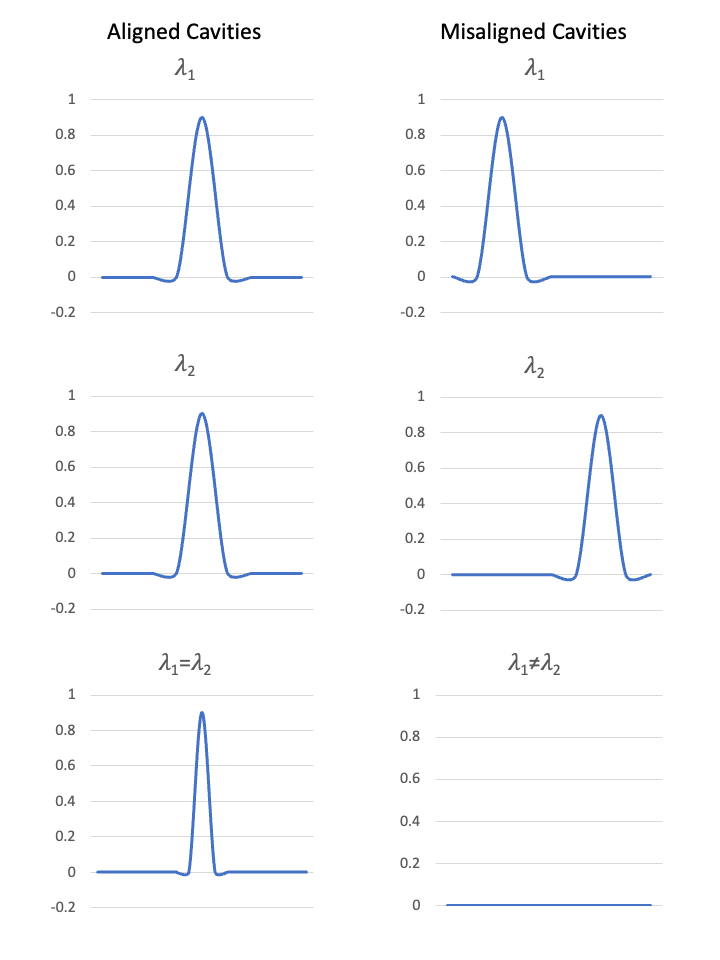

To further reduce the bandwidth, a second cavity can be stacked on top of the first. This is accomplished by literally depositing the second cavity’s optical stack directly on top of the first. The 2 cavity filter will be narrower than the single cavity filter. For further narrowing, more cavities can be deposited – four or five cavity stacks are common. However, if the film thicknesses are slightly off then the center of the two cavities will not be aligned at the same wavelength, and they will cancel each other out instead of narrowing the bandpass.

For more information, you can read about the results and the potential applications in our recently published technical paper.