Posted on

In large-scale, high-volume silicon semiconductor production, such as for microprocessors and DRAM, manufacturers often prefer direct handling of wafers during the thin film deposition process. This makes perfect sense for mass-producing wafers that are all 300mm in size. However, in the compound semiconductor industry, multiple wafer sizes are quite common. It is not economically viable to have separate production lines for each wafer size, so typically wafers of different sizes all go through the same system.

For these high-mix environments, it is critical to minimize system downtime for wafer size changes. By using wafer carriers instead of direct handling of wafers, this downtime is completely eliminated.

Unique Demands in Compound Semi Production

Silicon semiconductor processing is well developed, and the wafers are all produced at standard sizes. Wafer size changes are rare, which makes the handling solutions highly standardized, stable platforms. However, the materials used in compound semiconductors are not as well developed. Volume device production, such as for diode lasers, has been ramping while substrate size increases continued to develop. This means older products tend to be produced on smaller substrates, and newer products tend to be produced on larger substrates.

For this reason, it is common in the compound semi industry to use different wafer sizes for different applications. This presents a couple of problems if using direct wafer handling. For one, tooling changes, such as shield or fixture replacement, will be required for different wafer sizes. And different sizes mean different weights, which needs to be accounted for by your handler. In high-volume manufacturing, these changes will increase system downtime and likely slow your production, which is an issue when high throughput is a requirement. It also leads to less production flexibility, since you will need to minimize that downtime.

Benefits of a Wafer Carrier

To address these challenges and improve uptime, you can use a wafer carrier instead of direct handling to run wafers of different sizes through one system. This becomes even more important if you are using a cluster tool and high-volume manufacturing software for process automation. When you use a wafer carrier, you don’t need to break vacuum for size changes. You can run them all together through the system to execute different processes without any hardware changes, exactly as you would if the wafers were all the same size.

This offers several key benefits:

- Throughput and productivity: If you’re using cluster architecture or any type of front-end option, it’s likely because you need to hit a very high throughput. Breaking vacuum and implementing tooling changes to accommodate different wafer sizes increases system downtime and sacrifices that productivity. With wafer carriers handling all wafers for you, you can maintain the throughput you need to meet tight manufacturing schedules.

- Greater flexibility for process control: In high-volume compound semi production, you already need to be able to efficiently handle complex coating processes. A wafer carrier gives you that ability through greater flexibility for your system. Pausing deposition for multiple runs based on wafer sizes only further complicates intricate recipes, but with a wafer carrier that is fully compatible with automation tools, you can streamline those operations.

- Higher return on investment: Meeting throughput demands and increasing your productivity will raise the ROI for your tool. In high-volume manufacturing, you are striving for a system that already delivers on ROI. A wafer carrier that is completely compatible with your configuration will help ensure that your system provides the highest possible return.

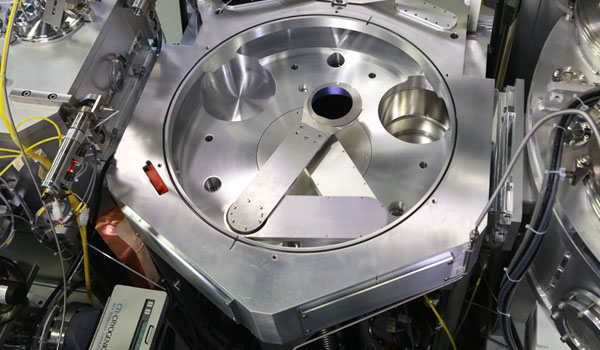

Denton Vacuum’s sputtering systems all feature a proprietary wafer carrier that can handle wafers of different sizes in the same system without breaking vacuum. While direct handling of wafers is the goal in certain applications, our thin film deposition tools are specifically equipped to handle coating processes where this is not a realistic solution. A configuration that can handle multiple wafer sizes will lend you the highest degree of process flexibility, and ensure that your system is completely scalable for different applications and throughput demands.

To learn more about implementing a wafer carrier in your thin film deposition process for compound semi manufacturing, contact us.