Posted on

Inverted cylindrical magnetron (ICM) sputtering is the optimal choice for applications that require ultra-uniform coatings on flat substrates. For example, ICM sputtering offers uniformity below 1% on standard 200mm wafers.

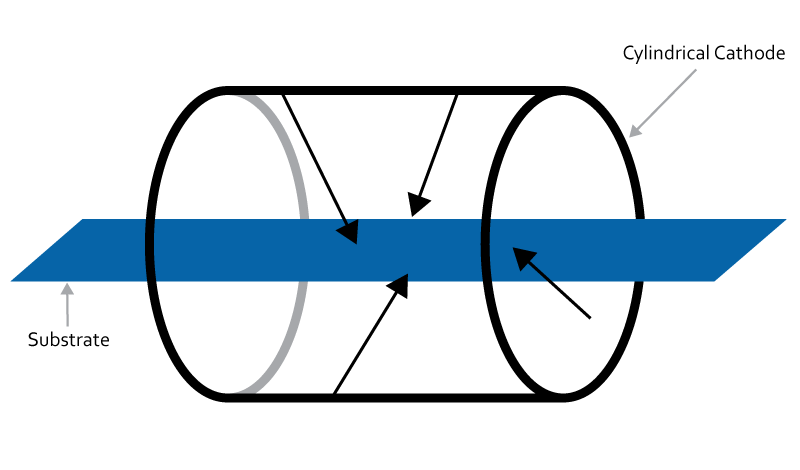

ICM sputtering follows the same steps as conventional magnetron sputtering except a cylindrical cathode is used instead of a planar cathode. Instead of sputtering up or down, the cylindrical cathode sputters inward. For complex 3D or cylindrical substrates, complete coverage with good uniformity can be achieved by positioning the substrate inside the cathode. For flat or curved substrates such as semiconductor wafers or optical components, extremely good uniformity can be achieved by positioning the substrate below the cathode. The uniformity is inherent in the cathode design and does not require complex shadow masks or motion.

Denton Vacuum owns the proprietary Isoflux cylindrical cathode portfolio, including all equipment, technology, and intellectual property. By adding Isoflux’s technology to our reliable sputtering systems, we can configure application-specific ICM sputtering solutions that deliver high-performance thin films at a low cost of ownership.

Applications

Ultrathin Semiconductor Wafer Layers

Advanced semiconductor devices require thinner, denser barrier and seed layers. Seed layers are used when there is a mismatch between a substrate and a desired layer. Seed layers are used to provide proper film nucleation (or initial growth conditions), and to ensure good adhesion of the desired film. Barrier layers provide electrical isolation between layers, where a high breakdown voltage is required.

With the dense, ultra-high uniformity films from ICM sputtering, thinner layers can be utilized while still meeting film requirements. This improves productivity and yield, enhancing ROI.

Curved Optics

You can read more about these applications here.

Optical coatings change the way an optic reflects light waves to meet specific application needs. ICM sputtering is ideal for depositing antireflective coatings, highly reflective coatings, and optical filters in flat and curved substrates.