Posted on

The most common types of physical vapor deposition (PVD) are magnetron sputtering and evaporation, which could be either thermal or electron beam (e-beam). How do you determine when to use which method? First, let’s take a look at how each one works.

What is Magnetron Sputtering?

Sputter deposition is excellent for materials with high melting points that cannot be evaporated. Magnetron sputtering is a versatile way to create very dense films with good adhesion. Magnetron sputtering is a plasma-based coating method that generates a magnetically confined plasma near the surface of a target. Then, positively charged energetic ions from the plasma collide with the negatively charged target material and atoms from the target are ejected or “sputtered”, which then deposit on a substrate or wafer.

Why Use Magnetron Sputtering:

- Excellent precision of film thickness, and density of film coatings – achieve denser coatings than evaporation

- Perfect for metallic or insulating coatings with specific optical or electrical properties

- Can be configured with multiple magnetron sources

What is Resistive Thermal Evaporation?

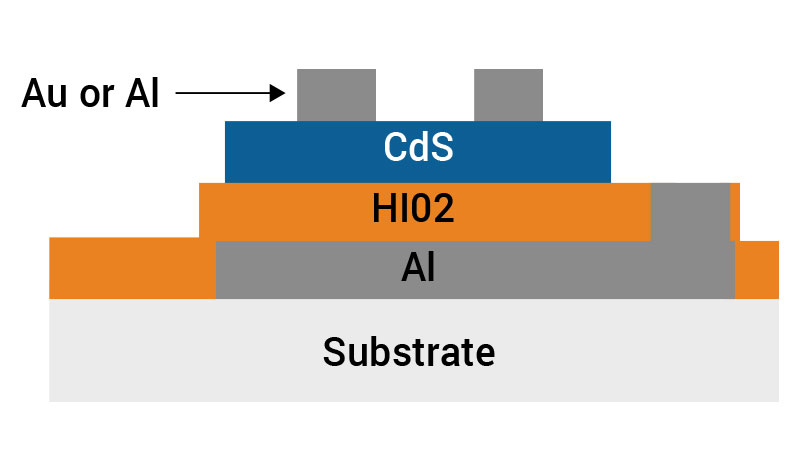

Resistive thermal evaporation is perhaps the simplest form of PVD. It normally uses a resistive heat source to evaporate a source material within a chamber. The evaporated material rises in the chamber via thermal energy, ultimately coating a substrate with a thin film. This process can be used for metals or nonmetals and is a good choice for electrical contacts.

Why Use Resistive Thermal Evaporation:

- Cost effective way to create thin films of metals or nonmetals with lower melting temperatures

- Can be used for indium bump deposition used in wafer bonding

- Higher deposition rates than sputtering

What is E-beam Evaporation?

E-beam evaporation is a thermal evaporation process that allows for the direct transfer of a larger amount of energy into the source material than is possible with thermal evaporation. This permits the deposition of materials with high melting temperatures, such as gold. In this method, the evaporation material is placed in either a crucible or a water-cooled copper hearth, where it is then heated by an electron beam. The heat causes evaporation of the source material, which then deposits onto the substrate.

Why Use E-beam Evaporation:

- Works for a wide variety of materials, including those with higher melting points that cannot undergo thermal evaporation

- Delivers better step coverage than sputtering or chemical vapor deposition (CVD)

- Offers a higher material utilization efficiency and higher deposition rates than sputtering

- Compatible with a second ion assist source, which allows for pre-cleaning or ion assisted deposition (IAD)

There is no one thin film deposition method that is the right choice for every application. All three types of PVD offer their own benefits and should be selected based on your requirements. If you’re having trouble selecting the method that’s right for you, take our short online assessment and one of our experts will walk you through the specification process.