Posted on

Repeatability is a key factor in any production process. Along with uniformity, it ultimately determines the yield of any thin film deposition process. When designing a thin film system configuration for high-volume manufacturing, repeatability becomes especially paramount.

Why is Repeatability Important?

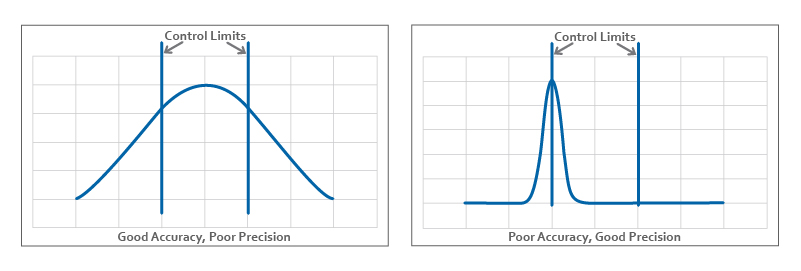

Accuracy (hitting the middle of a spec) and precision (repeatable results) are the two main drivers of yield. The two charts below both represent 50% yield, but for very different reasons.

A process that hits the middle of the spec on average but has low yield is not in control, which may be a difficult production challenge to overcome. A process on the edge of the spec with high precision, however, is a much simpler challenge. Most process engineers would much rather tune a highly repeatable process to a different midpoint than address all the possible reasons for poor repeatability.

It’s great if your thin film system enables high deposition rates, but without a repeatable process, the quality of those thin films may vary. Repeatability enables lower yield loss and higher net throughput, which are critical for high-volume production and long-term low cost of ownership.

Still, there has to be a balance between the need for repeatability and the need for a high throughput. For example, ion beam deposition offers the highest precision out of any deposition method, so it’s an excellent choice for repeatability. However, it’s also the slowest and most expensive method, so it may not be not very cost-effective or realistic for high-volume manufacturing.

Tips for Improving Repeatability

Here are a few methods and tools you can use to improve repeatability when manufacturing at a high throughput:

- Preventative maintenance: To achieve repeatable results, the equipment you’re running needs to be in top-notch condition, so there are no unpleasant surprises during the production process. Performing scheduled maintenance addresses those issues before they even occur.

- In-situ controls: With in-situ controls like a plasma emission monitor (PEM) or an optical monitoring system (OMS), you can closely monitor the deposition process and gain feedback in real time. These controls make the necessary adjustments (for example, regulating the gas flow in reactive sputtering) to ensure every substrate is coated to the exact specs needed, eliminating inconsistencies or errors.

- Standard process module: Using a standardized process module will help you preserve key process steps while scaling up for throughput needs. A standard module can be configured with any front-end to increase efficiency while consistently producing the same quality thin films.

- Automation and robotics: Introducing automation to your process of record will help you streamline the process and maintain consistency throughout every run. Pairing it with capable software that can accurately build and execute complex recipes also helps eliminate errors, which improves repeatability.

- Proven equipment with designed-in reliability: Equipment reliability plays a role in repeatability across each run. When a configuration is specifically designed to provide reliability, it will naturally increase system uptime while also ensuring the results of the deposition process are reliable as well.

- Improve precision for better control: A configuration that prioritizes precision will give you better process control over key specs like thin film thickness and uniformity across the substrate. With better control, you’ll be better positioned to achieve repeatability across your entire process.

For more details on how to improve key performance specs, download our technical paper, “Optimizing Source Location for Control of Thickness Uniformity”.