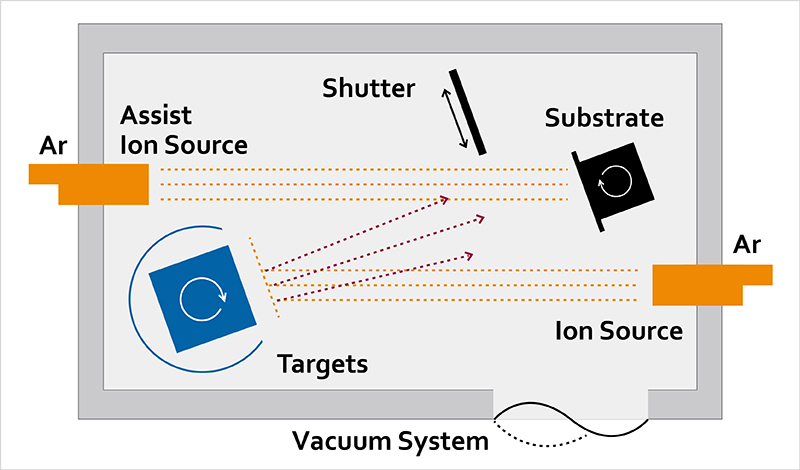

Differences in Grain Size Between Deposition Methods

Posted on

Grain size refers to the size of the individual crystallites or particles that compose a solid metal. Grain size, as well as the boundaries between the grains, are important factors for determining physical properties of the entire metal. In thin film deposition, if the particles are deposited with high energy, and there is a high… Read More