Posted on

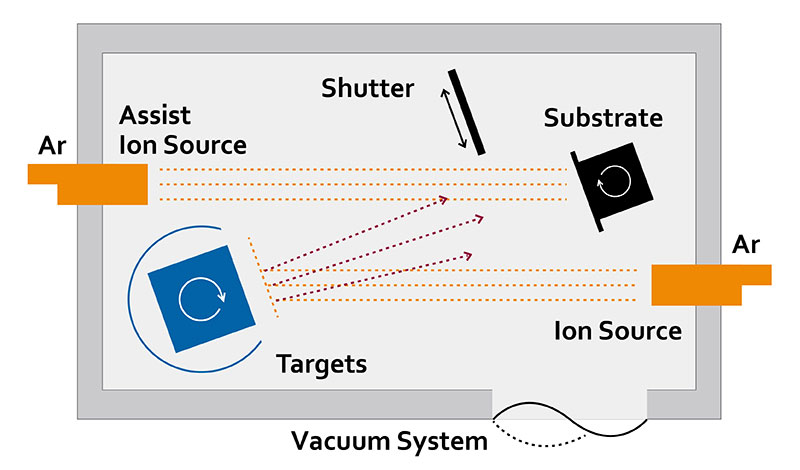

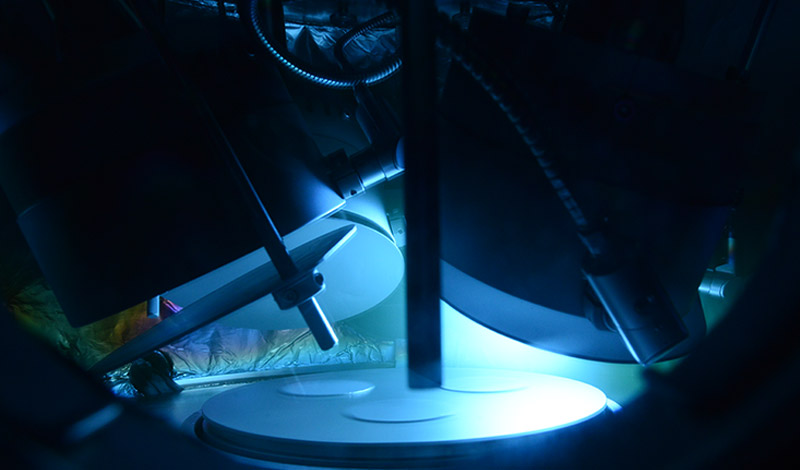

The opto-electronics and display industry is expecting to see significant growth in several LED-driven sectors over the next decade. Precision thin film deposition will play an important role in boosting the performance of the various end-user applications that are being fueled by this growth, particularly LED displays. Types of LED Displays LEDs, or light-emitting diodes,… Read More