What is Magnetron Sputtering?

Posted on

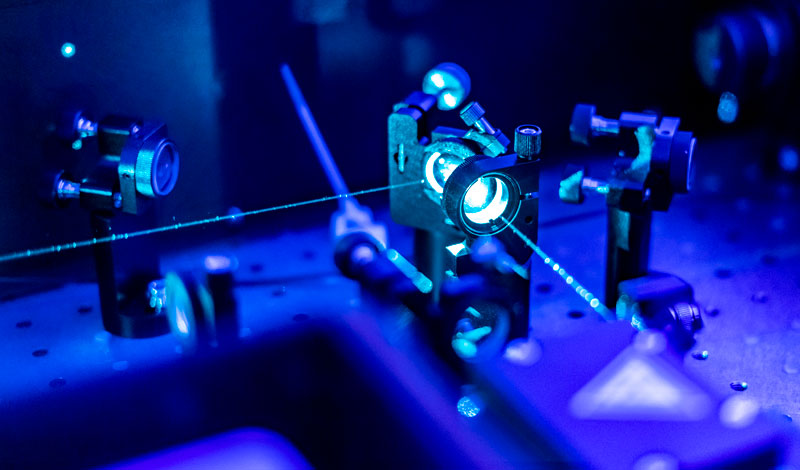

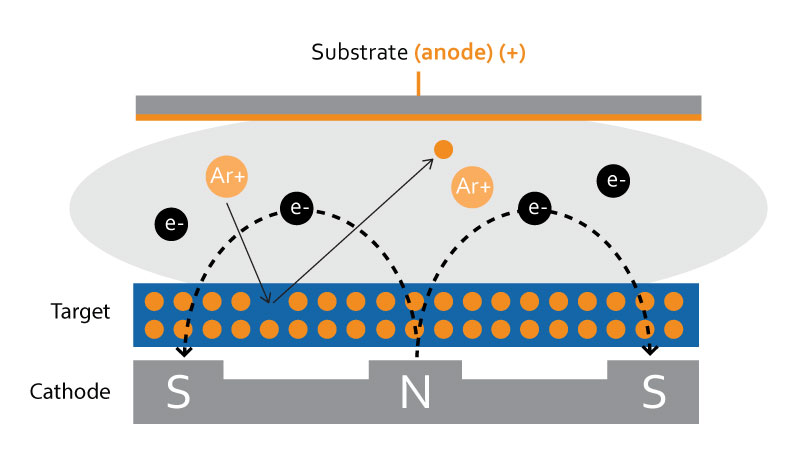

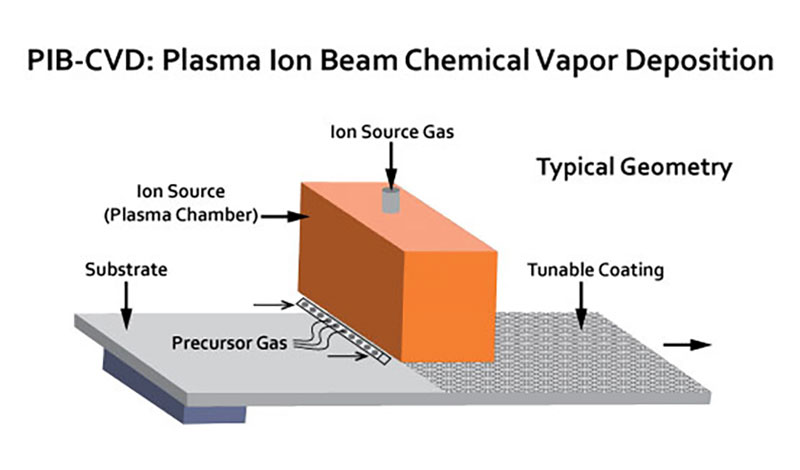

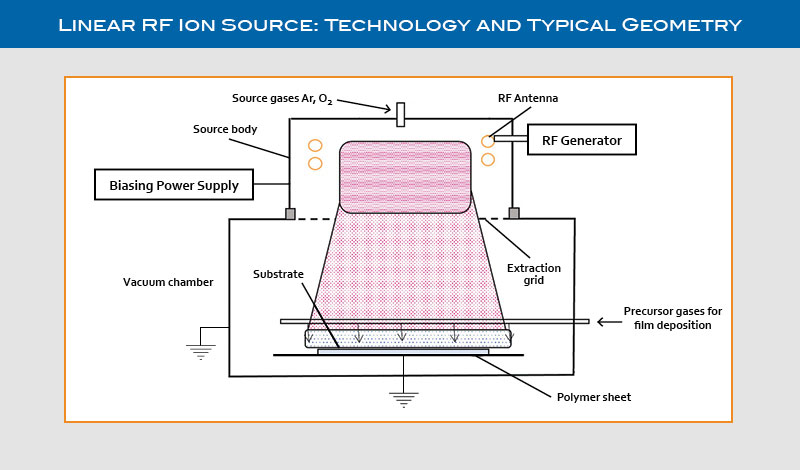

Magnetron sputtering is a plasma-based technique for physical vapor deposition (or PVD) coating that creates dense films with good adhesion. It is excellent for depositing materials with high melting points that cannot be evaporated, and it has the highest scalability of any PVD type. Magnetron sputtering provides excellent precision in film thickness and density of… Read More