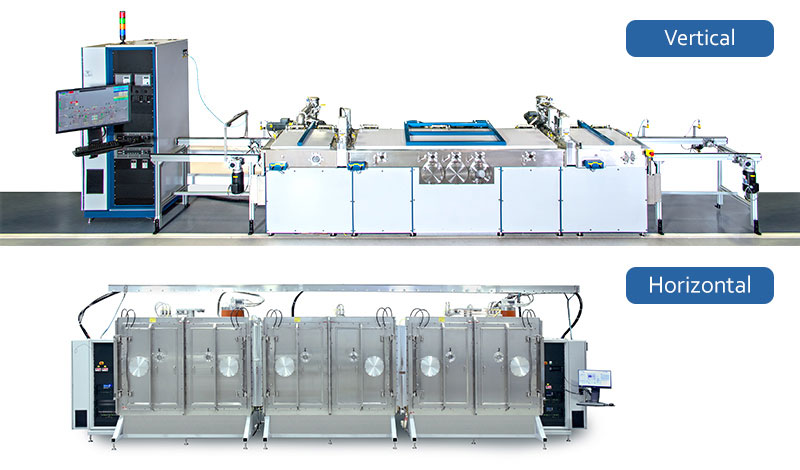

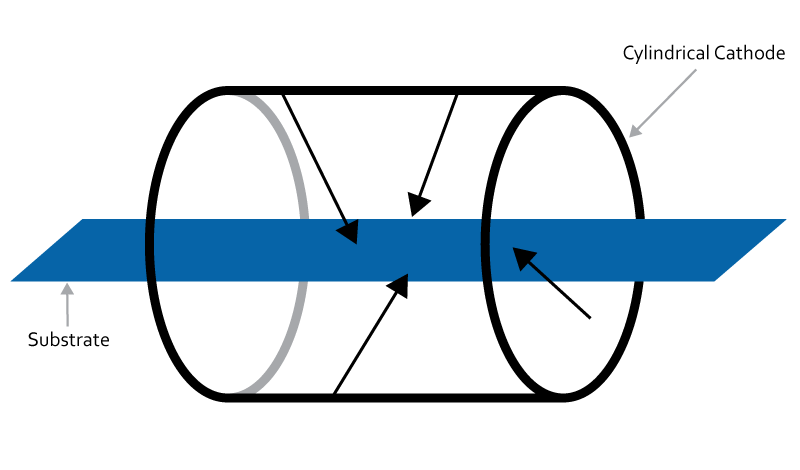

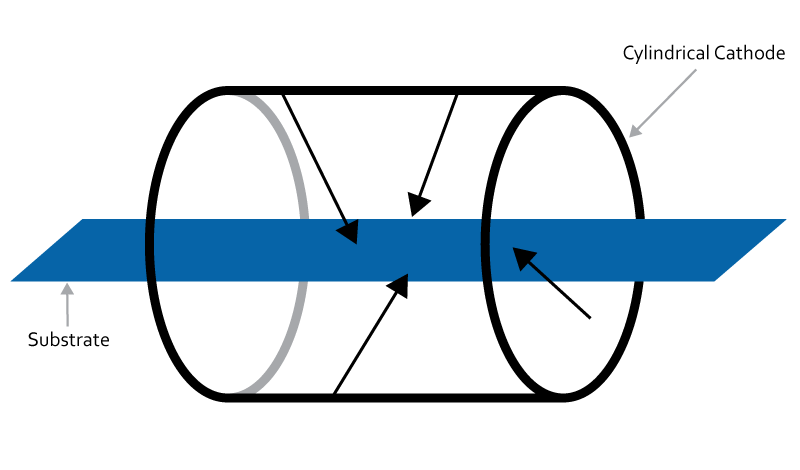

Benefits of an Inverted Cylindrical Cathode Configuration

Posted on

An inverted cylindrical cathode configuration, compared to a planar or confocal configuration, has a few notable benefits because of its highly unique design. Unlike most cathode arrangements, where the cathodes sputter down, up or across the chamber, an inverted cylindrical cathode sputters inward toward the center of the cylinder. This offers several advantages for precision… Read More