Denton Receives Patent for Linear Plasma Ion Source

Posted on

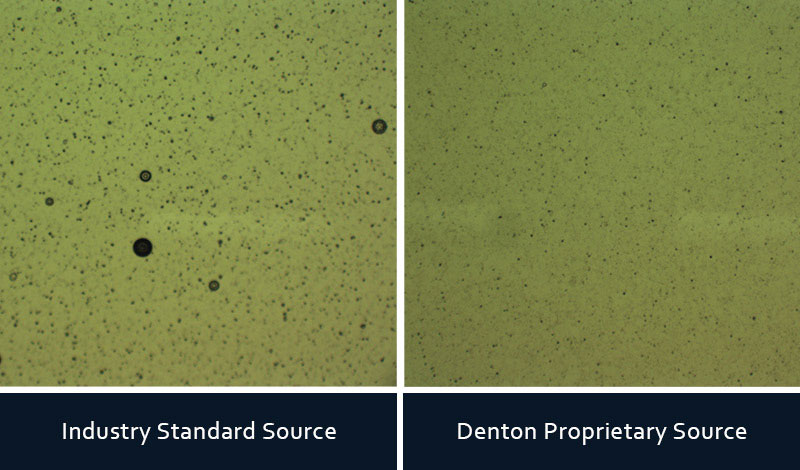

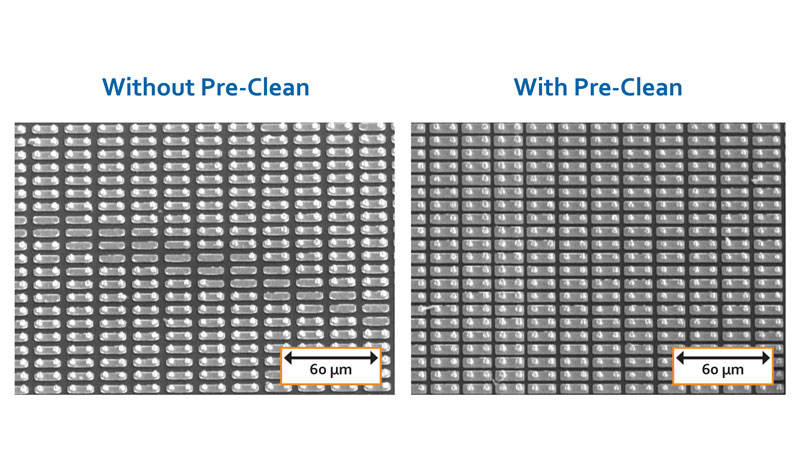

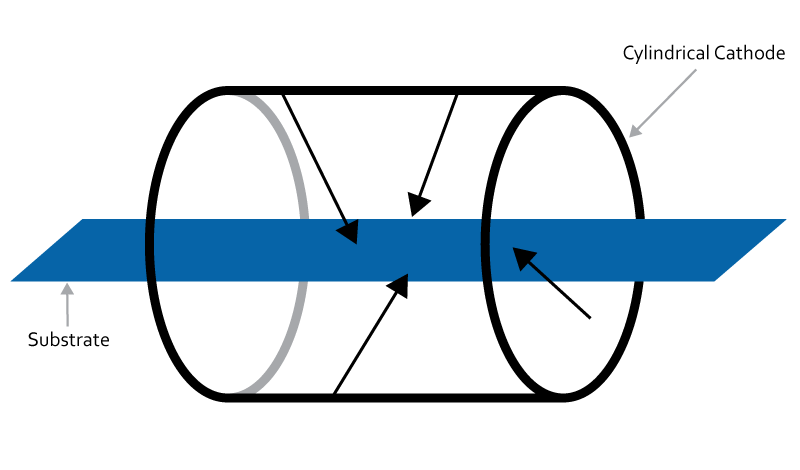

Denton Vacuum was recently assigned U.S. patent number 10,815,570 for a linearized energetic radio-frequency plasma ion source. This source is designed as a large area, filament-free source that is fully compatible with high-throughput, in-line sputtering systems. Some of the unique, patent-protected features of this source are: Benefits of Linear Ion Sources Denton’s linear ion source… Read More