Posted on

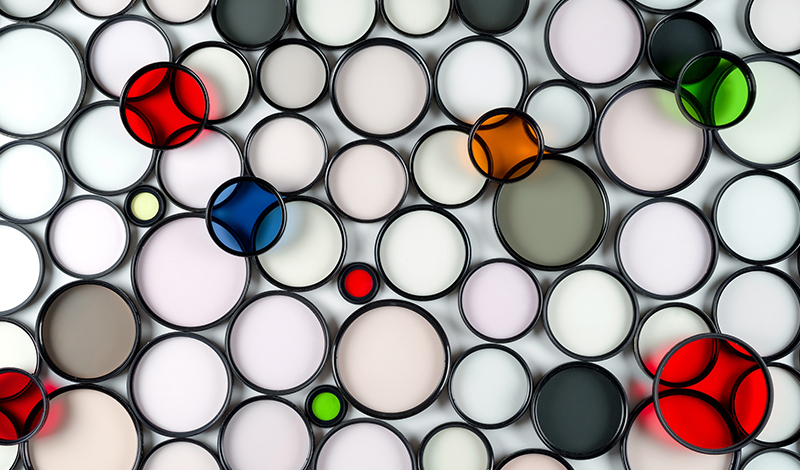

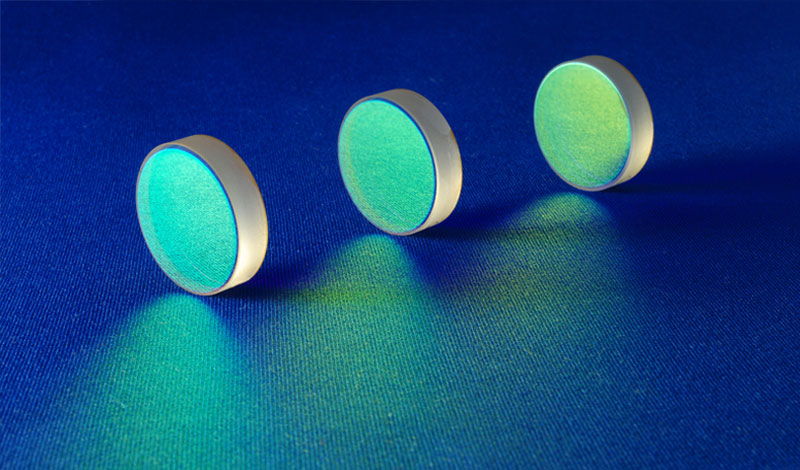

To create more precise thin films, manufacturers often include an ion source to their thin film deposition system configuration. By using an ion source, manufacturers can produce an ion species that has specific properties during deposition. The source controls the energy, trajectory and reactivity of the ions it produces, helping to create a thin film… Read More