Posted on

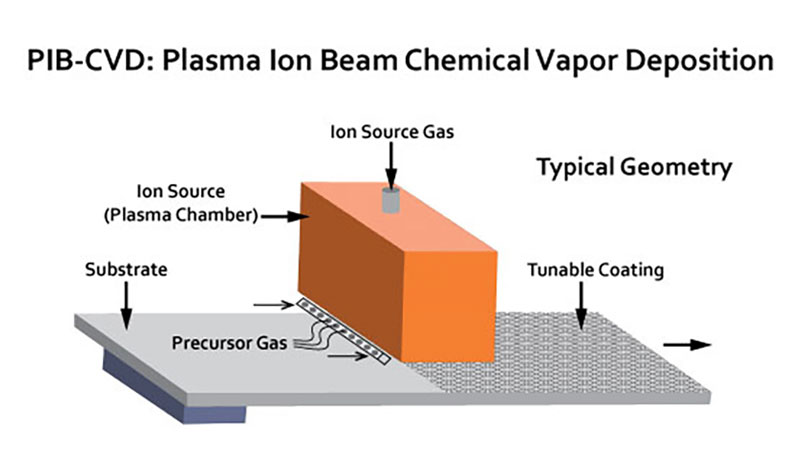

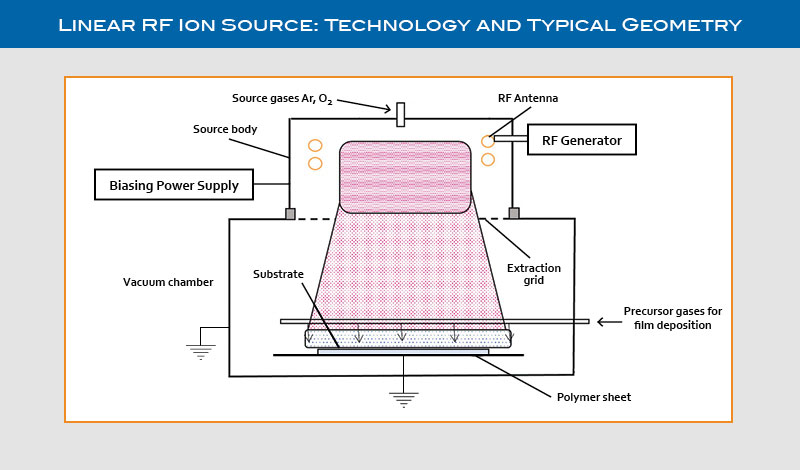

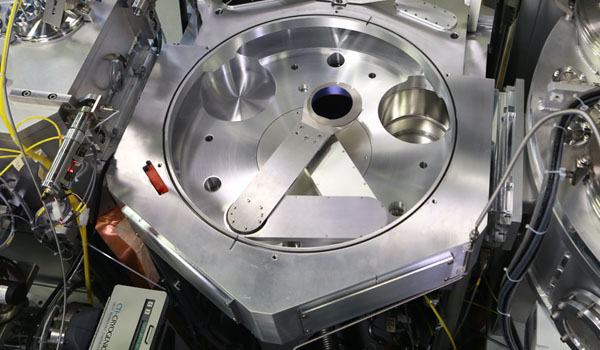

In thin films obtained by Chemical Vapor Deposition (CVD), chemical reactions are driven by applying heat to the substrate to be coated or to the area immediately around the substrate. Reactive precursor gasses are then introduced into the deposition chamber and react immediately with the heated substrate surface or combine to form new compounds that… Read More