Posted on

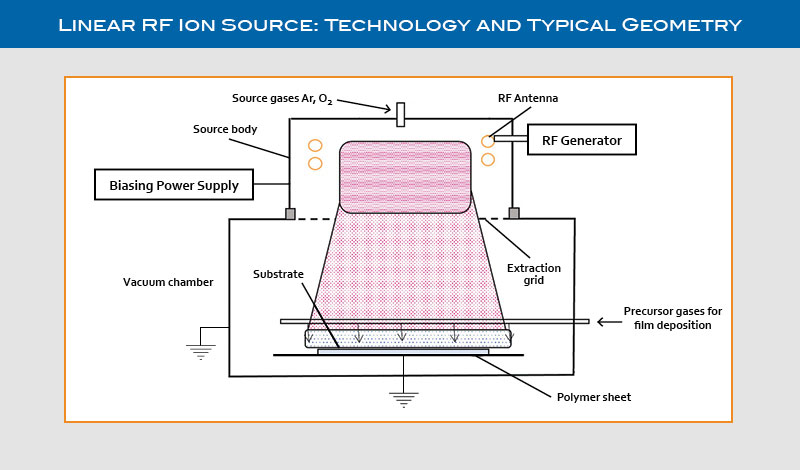

Traditional ion beam sputtering (IBS) provides excellent control over ion energies and thin film stoichiometry, making it the process of choice for sputtering metals and dielectrics for applications such as vanadium oxide microbolometers and VCSELs. Still, IBS has various challenges in meeting the necessary standards for applications in which a high degree of precision and… Read More