Posted on

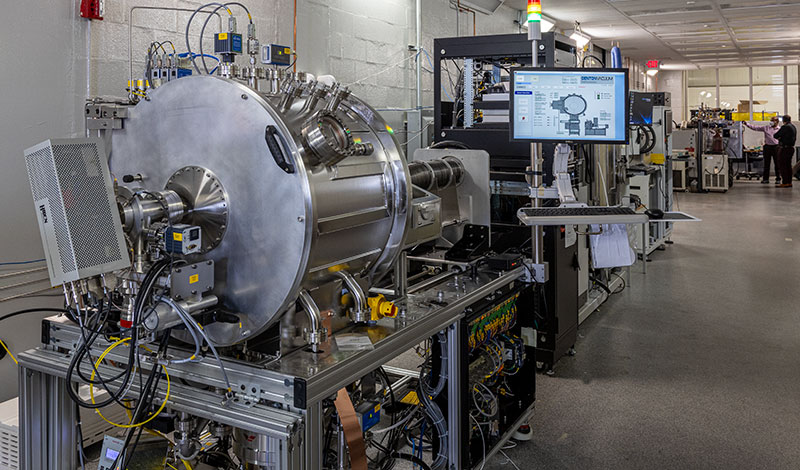

Magnetron sputtering is a versatile deposition technique that creates very dense films with good adhesion. It can easily deposit materials with high melting points that cannot be evaporated. Denton Vacuum’s magnetron sputtering systems are highly configurable with multiple cathode options to meet the specific requirements of different applications. In this article, we discuss the multiple… Read More